On November 26, 2019, SW Machine Tool Company (hereinafter referred to as SW) from Germany gathered at Chengdu Airport Hotel and invited nearly a hundred colleagues from the mechanical processing industry in Sichuan and Chongqing to discuss the technology and experience in the field of efficient metal processing. In their speeches, both parties expressed their hope to take this opportunity to showcase the top machine tool technology and advanced tool application technology in the industry to users. Through customized products and specialized services, they aim to make automotive industry users more competitive. They also hope to have in-depth exchanges with industry technicians through exchange meetings to jointly explore and solve problems encountered in the mechanical processing process.

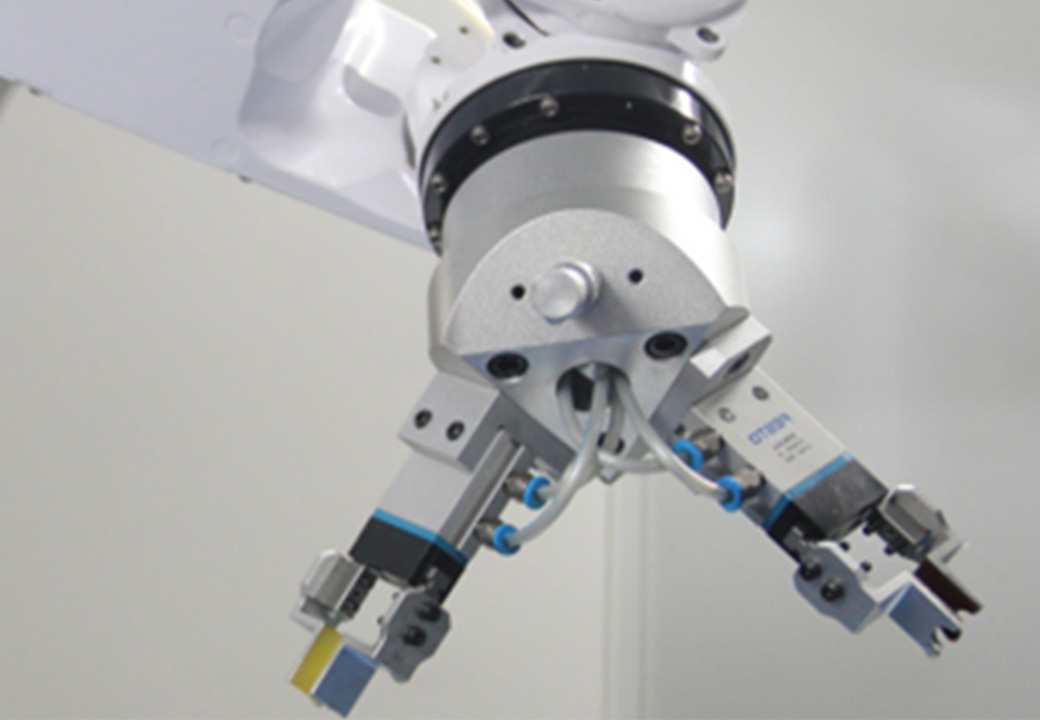

During the meeting, Mr. Wu from SW introduced the high efficiency of multi spindle machining and the flexibility of modular automatic solutions, and shared application cases from fields such as aviation, automotive, and hydraulic. Mr. Zhao from Sentai Inge subsequently shared advanced tool application technology and demonstrated Inge's strength through case data. The first case is the optimization of the valve plate project. In response to the burr problem in aluminum alloy processing, Ingersoll Rand adopted a special blade structure to effectively improve the quality of the processed surface. Not only did it ensure the flatness requirements, but it also effectively suppressed the generation of burrs, improved tool life, saved a total annual production cost of 545400 yuan, increased production capacity by 14.85%, and fulfilled the promise of reducing costs and increasing efficiency for customers with practical actions. In response to the optimization of a steering knuckle project for an electric vehicle factory, when the optimized process of a foreign company could not provide sufficient production capacity, Ingersoll Rand saved 29.7s of processing time per piece and increased efficiency by 24% by optimizing the tool scheme. This has been proven by facts; Efficient processing has not ceased;.

Old saying“ To do a good job, one must first sharpen their tools; , As a high-end machine tool, SW's strict requirements must also extend from itself to the supporting tools, and users choosing SW machine tools represent their high efficiency and quality requirements for metal processing. Ingersoll Rand's solution has won double recognition in the face of the dual high requirements from machine tool manufacturers and users. At 6 pm in the afternoon, the technical exchange seminar came to an end, and both parties and guests had on-site discussions and exchanges to further discuss the opportunities and challenges encountered in efficient processing and deepen mutual understanding. During the dinner party, several lucky users won prizes, and everyone spent a fulfilling day surrounded by fine wine and delicious food.

Number of views: 23

Number of views: 23 Date: 2025-04-25

Date: 2025-04-25